| Cover Story

From Comilla

Haripada's Haridhan:

A Farmer's Pride

Zakir Azad

The 1890 Tripura Gazzetteer tells us that a woven craft existed in the area which employed thirteen thousand men and two thousand women weavers. Among them most were Hindu in religion and came from Mainamoti, Chandina, Gauripur, Nobinagar, Kalikachha, Dhamti and Borkamta. In Mainamoti were made brightly coloured lungies in check design as well as sarees and gamchhas. The 1890 Tripura Gazzetteer tells us that a woven craft existed in the area which employed thirteen thousand men and two thousand women weavers. Among them most were Hindu in religion and came from Mainamoti, Chandina, Gauripur, Nobinagar, Kalikachha, Dhamti and Borkamta. In Mainamoti were made brightly coloured lungies in check design as well as sarees and gamchhas.

These cost between taka two and five in the currency of that time. The weavers from Shorail, Kalikachha and Nabinagar used to make very good quality dhuties and bed sheets. These used to cost from taka two to five a pair depending on their quality.

Pradip raha, now nearing the age of 58, lives in Comilla and is known for his business of Khadi material. Tourists from within the country and abroad visit his store of pure Khaddar material whenever they go to Comilla. There is nothing unworthy of being bought at his store. Pradip Babu tried his hand at the weaving industry but he now prefers to deal with Khadi materials. He says that there is still a lot of demand for this particular type of material, especially because clothes made with this material are now being made in newer and more modern designs.

When asked if the prices have risen compared to what they used to be, he says that it is natural with time. Materials have become much costlier than they used to be. For instance, a khadi dress that could be purchased at a certain price now, one could buy more than one dress at the same price before. There are a lot of reasons behind this, like lack of good quality labor, electricity load shedding and a rise in the general price of things. He says that even though a number of many competent weavers had left Bangladesh after the liberation war, there are still many highly skilled weavers who do good work, even with no formal training of the art.

Earlier, the hard working people of our country used to do everything on their own, starting from performing their daily necessities to sewing their own clothes rather than buying things from outside. It is this hard work and dedication of the people of Shorail, Comilla that had made them well-known to the rest of the subcontinent. The earlier generations were independent in most matters and that was why people respected them.

Comilla has been playing an influential role in creating woven crafts since the days of the Mughals. There were numerous weavers in the Tripura state during the 17th century. The 1890 Tripura Gazetteer tells us that a woven craft existed in the area which employed thirteen thousand men and two thousand women weavers. Among them most were Hindu in religion and came from Mainamoti, Chandina, Gauripur, Nobinagar, Kalikachha, Dhamti and Borkamta. In Mainamoti were made brightly coloured lungies in check design as well as sarees and gamchhas. These cost between taka two and five in the currency of that time. The weavers from Shorail, Kalikachha and Nabinagar used to make very good quality dhuties and bed sheets. These used to cost from taka two to five a pair depending on their quality. Woven craft was mainly concentrated within the areas of Moenamoti, Muradnagar, Gauripur and Chandina. These weavers who had been practising this craft for generations were apt in this field long before the craft became famous in Europe. Even when the demand for material imported from London and Manchester was high, the demand for material woven within the country remained unaffected. Apparels of modern design were made from the posh imported material whereas the everyday clothing of the people of the country, such as dhuties for Hindus and lungies for Muslims, were made from our own material. Comilla has been playing an influential role in creating woven crafts since the days of the Mughals. There were numerous weavers in the Tripura state during the 17th century. The 1890 Tripura Gazetteer tells us that a woven craft existed in the area which employed thirteen thousand men and two thousand women weavers. Among them most were Hindu in religion and came from Mainamoti, Chandina, Gauripur, Nobinagar, Kalikachha, Dhamti and Borkamta. In Mainamoti were made brightly coloured lungies in check design as well as sarees and gamchhas. These cost between taka two and five in the currency of that time. The weavers from Shorail, Kalikachha and Nabinagar used to make very good quality dhuties and bed sheets. These used to cost from taka two to five a pair depending on their quality. Woven craft was mainly concentrated within the areas of Moenamoti, Muradnagar, Gauripur and Chandina. These weavers who had been practising this craft for generations were apt in this field long before the craft became famous in Europe. Even when the demand for material imported from London and Manchester was high, the demand for material woven within the country remained unaffected. Apparels of modern design were made from the posh imported material whereas the everyday clothing of the people of the country, such as dhuties for Hindus and lungies for Muslims, were made from our own material.

Although the import of foreign materials was banned during the struggle for independence, our own weaving industries remained unaffected. The import of high quality Madrasi lungies was also banned at the time and that was when our own weavers reached new levels of perfection in the case of lungi weaving. The lungies made within the country were of the same high quality as those imported from Madras. The import of these lungies became totally banned after independence, allowing local weavers to flourish even more, and today, the quality of lungies made in Ramchandrapur, Gauripur and Muradnagar of Comilla district is better than those made abroad. Sarees, Shawls, Gamchhas, handkerchief and Satin mosquito nets made by these weavers are well known within the country and abroad.

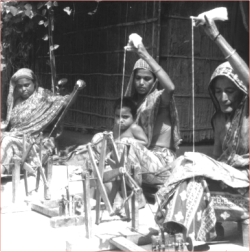

Shyamal Shaha of Chairmura Nabapur has been in the Khadi business for a long time. He is now ninety years old and spends his days lying in an easy chair most of the time. Even though he has poor eyesight, he can tell the quality of a woven cloth just by touching it. All four of his sons are also in the weaving business. They have no formal training and learned all that needed to be learnt from their experienced father. In fact, none of the weavers in Chadinar village has any formal training. All they possess is experience acquired over time. It is really amazing to see how impressive their intricately woven clothes are. With time, the girls in the family also started to work as weavers. However, Khadi work is done only by aged and experienced weavers. Thread work designs and hand paintings are mainly done by women. learned all that needed to be learnt from their experienced father. In fact, none of the weavers in Chadinar village has any formal training. All they possess is experience acquired over time. It is really amazing to see how impressive their intricately woven clothes are. With time, the girls in the family also started to work as weavers. However, Khadi work is done only by aged and experienced weavers. Thread work designs and hand paintings are mainly done by women.

Apart from Comilla's legendary woven art, the khadi work of this area is of a quality good enough to compete with any type of cloth from any part of the world. Mahatma Gandhi's exemplary principles and protests against foreign cloth inspired the initiation of Khadi work in Comilla. A branch of the Nikhil Bharat Tantubai Samiti was founded in Comilla which helped promote the exceptional products of the Khadi industry in Kolkata, Mumbai and Chennai.

After the partition of India in 1947, Khadi work was almost on its way to extinction due to various changes in the political and social environments. Comilla also suffered the effects of those changes.

After the language movement of 1952, Dr. Akhter Hamid Khan, who was a Professor at Victoria College and the Director of the Bangladesh Academy of Rural Development, Comilla, along with the then Governor Firoz Khan Noon took a lot of trouble to found “The Khadi and Cottage Industries Association”. A training center for Khadi and Khaddar work was also founded. In this way and with the cooperation of the Government of the time, the near-dying art of Khadi and Khaddar work was rescued from extinction and the work has retained its excellent quality ever since.

After the liberation of Bangladesh, Khaddar work again flourished and made a name both at home and abroad, making its home district Comilla wellknown and famous all over. The weavers of Comilla have kept up with the changes in design with time, and they now follow the modern designs of Madras and Bombay Corporationss to keep their work up-to-date and suitable for the current styles of clothing. This has brought a touch of modernity to the ageold khaddar art of Comilla. A few names that must be mentioned when speaking of Khaddar art of this region are Prabodh Das, Taruni Mohan Raha, Dinesh Babu, Manmohan Dutta, Shantosh Dutta, Samar Majumdar, Swapan Majumdar, Bahar Mia, Jairam Shaha, and Shankar Babu. These persons have been related to the Khadi industry by family tradition and they have relentlessly worked to keep this art alive and vibrant. After the liberation of Bangladesh, Khaddar work again flourished and made a name both at home and abroad, making its home district Comilla wellknown and famous all over. The weavers of Comilla have kept up with the changes in design with time, and they now follow the modern designs of Madras and Bombay Corporationss to keep their work up-to-date and suitable for the current styles of clothing. This has brought a touch of modernity to the ageold khaddar art of Comilla. A few names that must be mentioned when speaking of Khaddar art of this region are Prabodh Das, Taruni Mohan Raha, Dinesh Babu, Manmohan Dutta, Shantosh Dutta, Samar Majumdar, Swapan Majumdar, Bahar Mia, Jairam Shaha, and Shankar Babu. These persons have been related to the Khadi industry by family tradition and they have relentlessly worked to keep this art alive and vibrant.

Comilla's Khaddar is now well-known all over the country which is why we see so many stores that sell Khaddar material. The material is also sold in stores in markets like Gariahata in Kolkata. A new Khadi Market has been set up in Monohorpur of Comilla and on the Kandipara-Laksham Road. And even though the Khadi market called Bay-land shipping center is small in size, numerous customers come and buy from there Khaddar materials that suit their tastes.

Copyright

(R) thedailystar.net 2006 |