| From Jessore

Sticks Make Money

Zahidul Naim Zakaria

Some Bangladeshis dare to dream about becoming successful entrepreneurs in the midst of poverty. Even though this dream is hardly ever realised for those in rural settings, there are those that use their business instincts to achieve their dreams, in the process they elevate living standards for themselves and their communities. One such exceptional man is Md. Anwarul Islam. Some Bangladeshis dare to dream about becoming successful entrepreneurs in the midst of poverty. Even though this dream is hardly ever realised for those in rural settings, there are those that use their business instincts to achieve their dreams, in the process they elevate living standards for themselves and their communities. One such exceptional man is Md. Anwarul Islam.

Located in Sadir Ali village of Jhikorgacha upzilla in Jessore, Md. Anwarul Islam's business has shown considerable prosperity in the ice-cream stick making sector within a short time. Since most of the raw materials are found in nature, they can be easily collected. A massive output can be delivered within a short period of time due to easy mechanised production technology. The demand in the market is large enough to make for decent profits and add to the national income.

At first, ice cream sticks would be made out of bamboo. On a visit to India, Md. Anwarul Islam noticed how Indians use simple hand operated machines to produce massive quantities of ice cream sticks. Compared to making sticks out of bamboo in a manual production process, such mechanised production was significantly more efficient and therefore cost effective. During his stay, he learnt the ins and outs of the machine and how to operate it. He started to plan on how he could bring such machines back to Bangladesh and start an ice cream stick making factory here. He generated some funds by selling off a portion of his land and by taking a very small loan from the Rural Reconstruction Foundation, and used this money to import the machines from India.

THE PRODUCTION PROCESS OF ICE-CREAM STICKS: THE PRODUCTION PROCESS OF ICE-CREAM STICKS:

The main raw material used to make ice cream sticks are obtained from a tree called Pituli, which is available in large quantities in the wild. This tree is available throughout the year and the locals usually use it as fuel for cooking. Local dealers sell wood from the Pituli tree at Tk 3500 to Tk 4000 per 50 cubic feet.

Anwarul and his entire family work together. He employs 170 workers in his village, whose salary is based on the amount of work they do. Even at a staggering output of 300,000 sticks per day, he fails to meet the demand of the domestic market, which shows that the demand for ice cream sticks are increasing, ensuring a good price to producers. The growth in the market for ice cream sticks depends on the growth in the popularity of ice cream in Bangladesh, since the two markets are complementary in terms of supply.

Anwarul operates four machines, which he imported from India in 1990. The production process includes three stages. At first, a machine transforms the log wood into thin sheets of paper wood. Secondly, the paper wood is cut into shapes of straight ice cream bar sticks and into ice cream cup spoons by two different machines. Finally, the edges of the sticks are smoothened by another machine. These are all specialised equipment designed specifically for this purpose. The finished sticks are packaged and made ready for distribution by women workers.

In the first stage of the process, only four workers are employed; in the second stage, only two, and in the last stage only one worker is employed. The production process is capital intensive, although the packaging process is labour intensive with 150 workers dedicated only to packing the sticks. The ice cream bar sticks are packaged 1000 at a time using a thread of a specific length, but the ice cream cup sticks are actually counted one by one and packaged 25 at a time. Once packed, the sticks are sent to the market in large sacks.

Large stocks can be easily maintained in storage, since the sticks are not perishable. Risks of the business are minimised by the durability of the output, since the producer can easily draw up or down on his stocks according to market requirements. Wholesalers buy the sticks from producers in bulk and supply it to ice cream factories. Since the prices in the market are more or less stable, profits can be increased easily with expansion of production and gaining economies of scale. There is a seasonal variation of demand in the market, since demand for ice cream comes down during the winter, and Anwarul believes that export opportunities need to be created in order to stabilise overall demand for ice cream sticks.

His endeavour has generated employment opportunities for 170 poor families, amongst which 150 work full time and 20 work part time. Three quarters of his workforce comprises of women. Their work is to package the sticks. For packaging ice cream bar sticks, they earn Tk 1 per 1000 sticks, and for ice cream cup spoons, they earn Tk 2 per 25 sticks. Each of the employees earns approximately Tk 80 to Tk 90 per day, making their monthly earnings Tk 2400 to Tk 2700. The families of these workers are much better off now that both husband and wife are economically active, since most of these women would not have found any other means of earning a living. Because of this extra income, these poor families are able to send their children to school. Moreover, Anwar's project happens to be socially responsible, as amongst those 170 workers, he has employed 6 mentally/physically challenged individuals. His endeavour has generated employment opportunities for 170 poor families, amongst which 150 work full time and 20 work part time. Three quarters of his workforce comprises of women. Their work is to package the sticks. For packaging ice cream bar sticks, they earn Tk 1 per 1000 sticks, and for ice cream cup spoons, they earn Tk 2 per 25 sticks. Each of the employees earns approximately Tk 80 to Tk 90 per day, making their monthly earnings Tk 2400 to Tk 2700. The families of these workers are much better off now that both husband and wife are economically active, since most of these women would not have found any other means of earning a living. Because of this extra income, these poor families are able to send their children to school. Moreover, Anwar's project happens to be socially responsible, as amongst those 170 workers, he has employed 6 mentally/physically challenged individuals.

The production of ice scream sticks is environment friendly, since no chemical or plastic is used for production. Even if the final consumers dispose the sticks openly, it does not cause any negative externality or pollution. Once moist, the stick will decompose slowly and soften into the earth. Talcum powder and wax are used during the finishing process of the ice cream sticks, which do not pollute the environment. The usual waste of the paper wood from the production process can be used as fuel, so there is virtually no waste at all.

With easy access to raw materials and efficient production process ensuring quality, Bangladesh can think about ice cream sticks as an export item. Md. Anwarul Islam dreams about investing more money into his business, thus expanding it further. He dreams about supplying to the international market, for which he requires a certain degree of institutional assistance. He believes that such factories can easily be opened in other locations of Bangladesh, since the demand for ice cream sticks as one of the primary components of the final product is high in both domestic and international markets.

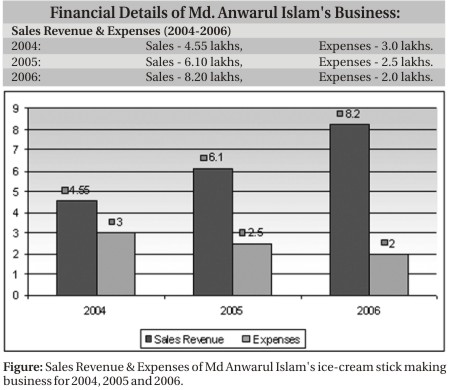

The figures show a steady yet rapid growth of sales whilst costs come down with mass production and attainment of economies of scale, thus increasing profits every year. Anwarul's business is an ideal model for the ice-cream stick making industry of Bangladesh.

Copyright

(R) thedailystar.net 2008

|