| She

From Pabna

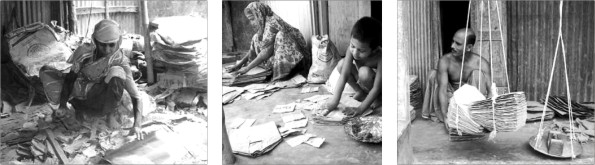

Paper Bags from Recycled Material

Ahmed Humayun Kabir Topu

Taslima Begum is a middle aged woman who has set up a small paper bag making initiative in her home in the village of Kuthipara in the municipality area of the district headquarters. Ten women workers are working in her small factory and earning money. Not only Taslima Begum herself but most of the poor women of this village have started making paper bags following this example. Making paper bags by recycling discarded material is the primary livelihood for the poorest women of this village. In fact, the village has come to be known as Thonga Para.

A survey found that over five hundred women here were engaged in this job. There are about 50 to 60 small packet factories here. “I struggled hard with my family when my husband was the sole earner of the family. Then I started making paper bags out of paper that was considered wastage,” Taslima said.

“I set up the small paper bag factory in my residence seven years ago investing just Tk. 3 thousand. Gradually the demand for paper bags increased and my factory became larger. Now there are at least ten women working in my factory,” she said. Now there is an investment of Tk. 1 lakh in factory. At least 7 to 8 hundred paper bags are produced in a day. I am glad that I am earning at least Tk. 10 to 12 thousand. Rowshonara, another poor woman of this village has been doing this job for the last 7 or 8 years. She is too poor to establish a small factory. “At least Tk. 20-25 thousand is needed to set up a small factory. I can't do that. So I am doing contract work”, she said.

Her husband Mokhles was an employee of 'Kalico Cotton Mill' earlier. After closing the mill her husband became unemployed again. Now he is a day labourer and wood chopper. His meager income is just not enough. So Rawshonara has to help out.

“Like me several hundred poorest women are producing bags with their own efforts. We don't get any help from the government to establish this business. No NGO works for our interests either,” Rawshonara said.

Talking with the people in this village it has been learnt that the workers used to buy the wastage cement bags from the market and recycled the stuff to make paper bags. The folding of the paper bag, or thonga, is done with gum. At least 7-8 packets are made from each bag. The production cost has gone up as the price of cement bags increased: it's gone from taka 3-4 to taka 7-8. Since thonga prices aren't correspondingly going up, the profits are falling.

There are men involved in this business too. Md. Majed is one of them. He has been doing this for seven years. He has a small factory and his whole family works on it. “At least 30-40 kg of paper bags is produced a day. But the profit margin now isn't all that good.”

With the ban of the polythene bag, paper bags should see a lot of demand. Majed and others are selling their products all over the country. “Wholesale businessmen used to buy paper bags from this Thonga Para. Karwan Bazar, Dhaka is the largest wholesale market of thonga,” Majed added.

Surveying the village it has been learnt that the poorest women are doing without any government assistance. “500- 600 women are dependent on the handicrafts business. But they don't get any help from the government,” told Md. Mojam Pramanik, the Ward Commissioner of Ward no. 15 of Pabna Municipality. The village of Thongapara is under that ward.

He also urged to the government to give assistance to the poorest entrepreneurs. The Ward Commissioner said it was his father who started the business back in the Pakistan days. But the real proliferation of these small factories has only taken place in the last eight years.

Copyright

(R) thedailystar.net 2008

|