Feature

Pabna

Handicrafts thrive in Ishwardi

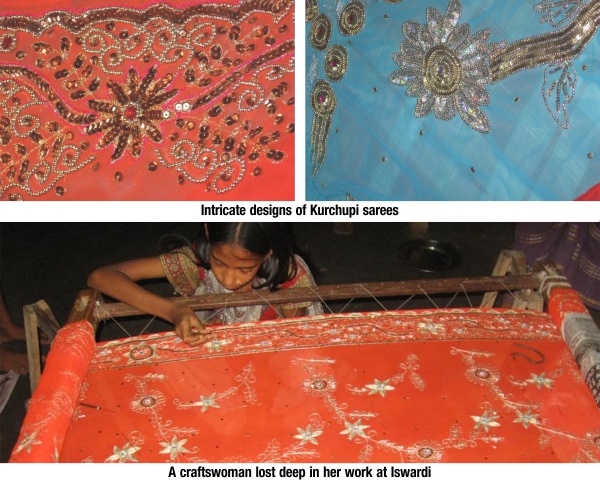

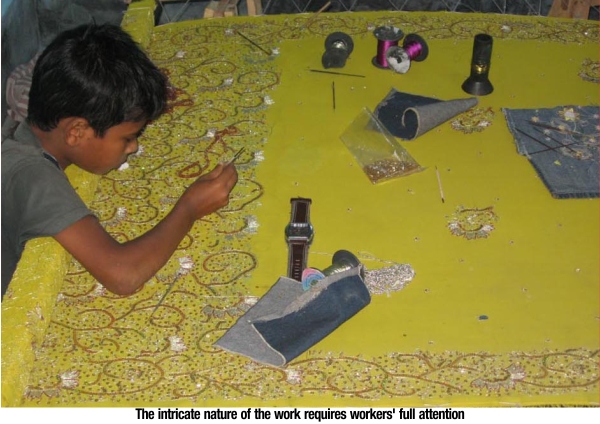

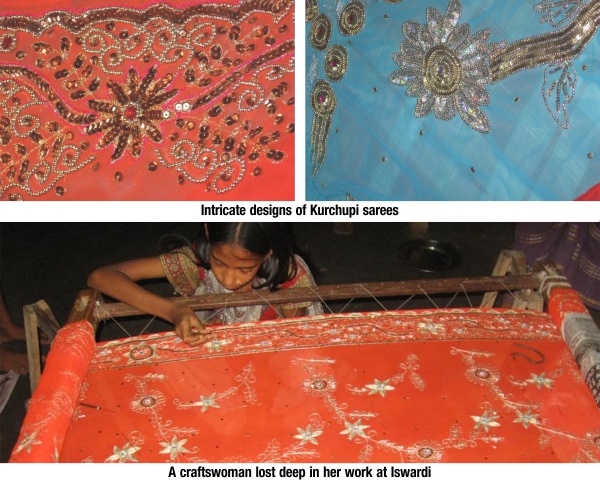

Women from every houses of Fateh Mohammadpur village were busy decorating sharees and clothes in their residences as the Eid-ul fitre came near knocking at the door. The hand-embroidery industries, known as the 'Karchupi Shilpo' gradually has grown up in the village in Ishwardi upazila under the Pabna district over the last decade

.....................................................................................

Ahmed Humayun Kabir Topu

The Fateh Mohammadpur village used to be known as Benarashi village in the District. The name came from the adept local skills of manufacturing fine quality of Benarashi and other luxurious cloths such as the Katan. But it is sad to say that the ancient heritage of such cloth production is dying out day by day. Due to commercialization of the cloth making industry, workers in this handloom sector are migrating to the ready made garments sector merely to survive the daily struggles and earning a minimum living.

But one positive aspect has arisen from the work migration trend followed by the workers. A large number of the Benarashi workers picked up hand embroidery, which is known as Karchupi Shilpa. This has become a lucrative business for many because of its high demand, so much so that the village is now recognized as the Karchupi Palli.

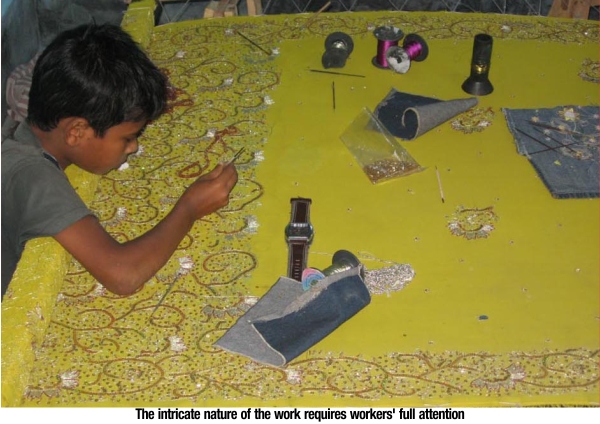

Badal Benarashi, a Benarashi and Karchupi factory owner says that mostly women engage themselves in this trade. These women are able to work from their homes. The art-form on cloth had very quickly grabbed the attention of people and demand for the decorative cloth increased drastically causing most women of the village to engage and be part of the profitable business.

Badal continued by saying that around 400 to 500 families are involved in this sector and earn a living through this profession in the village. He personally employs around 40 very busy workers in his small factory. The factory receives around 20 to 30 orders on a weekly basis on average. This number shoots up to as much as 50 per week during the holy month of Ramadan as Eid ul Fitr approaches. Badal continued by saying that around 400 to 500 families are involved in this sector and earn a living through this profession in the village. He personally employs around 40 very busy workers in his small factory. The factory receives around 20 to 30 orders on a weekly basis on average. This number shoots up to as much as 50 per week during the holy month of Ramadan as Eid ul Fitr approaches.

The willingness to pay for this product is absolutely dependent on the quality. Consumers prefer this over Indian products only because of the richness of the art and quality of the sharees. The village is home to nearly a dozen of the largest Karchupi factories in the country, making the area the largest Karchupi zone of Bangladesh.

The workers mainly work with cloths such as Katan, Jorjet, and Tissue and decorate them with materials such as Puthi, Stones, and Chumki. They turn them into gorgeous works of art. A full sharee is completed in 5 to 10 days, with 3 to 4 workers working on it simultaneously. The time varies based on the amount of work and the intricacy of the design to be embroidered.

Sharee manufacturing costs vary greatly, from 700 to 7,000 takas, which are sold at prices ranging between 2,000 to 12,000 takas. These are selling prices from the gates of the factories, which in turn reach even higher prices as they hit the marketplaces. The final retailers who sell to individual customers enjoy the greatest profit per sharee.

Copyright

(R) thedailystar.net 2011

|

Badal continued by saying that around 400 to 500 families are involved in this sector and earn a living through this profession in the village. He personally employs around 40 very busy workers in his small factory. The factory receives around 20 to 30 orders on a weekly basis on average. This number shoots up to as much as 50 per week during the holy month of Ramadan as Eid ul Fitr approaches.

Badal continued by saying that around 400 to 500 families are involved in this sector and earn a living through this profession in the village. He personally employs around 40 very busy workers in his small factory. The factory receives around 20 to 30 orders on a weekly basis on average. This number shoots up to as much as 50 per week during the holy month of Ramadan as Eid ul Fitr approaches.