Farmers’ Voice

Chittagong

Hope in the Hills

The Chittagong Hill Tracts Development Board in association with the government and ADB started a project in hilly areas of Bangladesh. Here, indigenous people are involved with jhum cultivation (slash-and-burn agriculture). However through this, forestation is negatively affected. Hills are damaged due to removal of trees. So, the project of upland settlement has been implemented. The goal was to discourage them to do jhum cultivation by involving them in rubber farming.

.................................................................................................

Shykh Seraj

It started in 1982 in Khagrachhari. Then it continued in the Bandarbans. Hundreds of people started rubber farming. From nursery to planting the trees, collecting rubber from grown trees, local people have worked hard in their business ventures. And, later a factory was built here. I went to Rajvilla in the Bandarbans to see the extension of the project and how local people are actually being benefited.

The scenario in this part of hilly areas was different. Different measures had been taken a long time ago to avoid the adverse affects of jhum cultivation. Rubber cultivation is one of them, an alternative, which has proved to be very successful. It helped develop the livelihood status of the indigenous people as well as to open up a new strategy towards restoring the environment. The scenario in this part of hilly areas was different. Different measures had been taken a long time ago to avoid the adverse affects of jhum cultivation. Rubber cultivation is one of them, an alternative, which has proved to be very successful. It helped develop the livelihood status of the indigenous people as well as to open up a new strategy towards restoring the environment.

Almost 26,000 acres of land were leased to 500 landless families from Rajvilla and Kahaloon Upazilla of Bandarban. Every family was given 5.25 acres of land. Land was allocated for housing and horticulture (1.25 acres) and rubber gardens (4 acres). Ten model villages were created to materialize this project.

I went to a rubber nursery, which is an ideal employment opportunity for rehabilitated people. The supervisor of this nursery, Khokan Alo Chakma told me about the productivity of rubber and how well the nursery is performing.

‘We have 6000 seedlings here and 300 are enough per acre.” I asked him about the quality of the seeds, in fact, I wanted to know how they are sure that these are the best quality. “We make these seedlings directly from the seeds. Then we do grafting”, replied Khokan. I came to know who were previously involved in the project. They were trained in Malaysia and they brought high yield variety rubber seeds. Members of rehabilitated families work in the nursery on a day-labour basis. People who were unemployed in the past have become financially stable.

“How much do you earn daily?” “Tk. 150.”

It was good to know that these labour can work round the year, providing them with a sustainable source of income. However, women workers get lesser wages than men (about tk. 100). But still, they have a peace of mind as they can fend for themselves. Around Tk. 85,000 was spent for a single family through the project which includes housing, nursery and rubber garden. “We have different plants here. Pineapple, guava, etc. We're producing and selling fruits and it's great for us.” On average, they earn Tk. 6000 to 7000 per month, which has helped them lead a comfortable life.

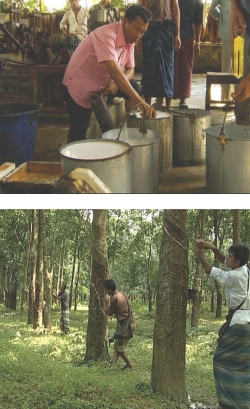

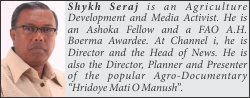

I actually went across the second rubber project of Rajvilla. The current project's trees were planted in 1995. Generally, rubber production starts within 7-8 years of plantation. They get seeds and seedlings from the nursery, three seeds from one plant. Seeds are later sent to nursery for germination. It takes 10-12 days to get seedlings. From early dawn, farmers start tapping the rubber trees every day. And within 9 or 10am, they start collecting rubber. As the day grows old, rubber gets thinner and the productions get lesser as well. So, they get busy in collecting rubber every morning. Milk-like raw material of rubber, in liquid form known as 'latex', is collected from tapped trees. I actually went across the second rubber project of Rajvilla. The current project's trees were planted in 1995. Generally, rubber production starts within 7-8 years of plantation. They get seeds and seedlings from the nursery, three seeds from one plant. Seeds are later sent to nursery for germination. It takes 10-12 days to get seedlings. From early dawn, farmers start tapping the rubber trees every day. And within 9 or 10am, they start collecting rubber. As the day grows old, rubber gets thinner and the productions get lesser as well. So, they get busy in collecting rubber every morning. Milk-like raw material of rubber, in liquid form known as 'latex', is collected from tapped trees.

These rubber farmers use a special kind of a tool, which you may call a rubber tapping knife. Rubber tapping is quite similar to collecting date-palm juice. I was talking to a rubber tapper regarding the whole procedure and time spent behind this work. He was actually tapping rubber from a tree with a bucket as he spoke to me. To make a about one kilogram of rubber, farmers have to collect from 10 to 12 trees. However production varies from tree to tree.

I found some women labours who were involved with rubber tapping. These women workers have a clear calculation. They can tap around 300 trees in 2 hours. They start tapping the trees very early in the morning and by 9 to 10am, they finish collection. They actually get 300 gms of dry rubber from one kg of latex. If they can collect 3 kgs of latex, they get Tk. 35.

On a good day, a hard working labour can earn up to tk. 350 even, but that is an extreme case, because it entirely depends on trees, on the production of latex. The great news is that most of them earn about tk. 10,000 per month and they can work round the year. This project has been implemented with a goal to develop the livelihood of the marginalized people. Now, their financial condition is much better. The living condition is much higher after rehabilitation. Moreover, they are receiving 60% money of their sold products and rest as bonus in different festivals. I visited the rubber factory in Nawapara. The authority has made an aim to produce rubber worth 7,000 crore taka per year from this factory! It takes 3 days of various procedures to produce raw rubber. But the machinery used at the factory is not latest and needs to be upgraded.

Many people have found the right path of life but still there are many who are yet to be rehabilitated. They also need to be included in the project. The project is successful not only because it rehabilitated those it targeted, but also because now it's running on self-entrepreneurship without any external aid. This element of sustainability needs to be built in to every development project, or else rehabilitation will be short lived. This project needs to move forward according to the locals. I talked with the Chairman of Chittagong Hill Tract Development Board regarding the issue. “We've given the ownership to 713 families in the 1st phase and 119 families in the 2nd,” said he. “And the rest will be given very soon. Government also has a plan to make a Rubber Board.” That is a promising thought.

This rubber project is surely a model for developing the highlands. There will be more families benefitted in the future through multiplier effects of the success of this project. Everyone's hoping to convert fallow lands to cultivable ones following the model, and since the model has become established, many will surely follow.

Copyright

(R) thedailystar.net 2012 |

The scenario in this part of hilly areas was different. Different measures had been taken a long time ago to avoid the adverse affects of jhum cultivation. Rubber cultivation is one of them, an alternative, which has proved to be very successful. It helped develop the livelihood status of the indigenous people as well as to open up a new strategy towards restoring the environment.

The scenario in this part of hilly areas was different. Different measures had been taken a long time ago to avoid the adverse affects of jhum cultivation. Rubber cultivation is one of them, an alternative, which has proved to be very successful. It helped develop the livelihood status of the indigenous people as well as to open up a new strategy towards restoring the environment.  I actually went across the second rubber project of Rajvilla. The current project's trees were planted in 1995. Generally, rubber production starts within 7-8 years of plantation. They get seeds and seedlings from the nursery, three seeds from one plant. Seeds are later sent to nursery for germination. It takes 10-12 days to get seedlings. From early dawn, farmers start tapping the rubber trees every day. And within 9 or 10am, they start collecting rubber. As the day grows old, rubber gets thinner and the productions get lesser as well. So, they get busy in collecting rubber every morning. Milk-like raw material of rubber, in liquid form known as 'latex', is collected from tapped trees.

I actually went across the second rubber project of Rajvilla. The current project's trees were planted in 1995. Generally, rubber production starts within 7-8 years of plantation. They get seeds and seedlings from the nursery, three seeds from one plant. Seeds are later sent to nursery for germination. It takes 10-12 days to get seedlings. From early dawn, farmers start tapping the rubber trees every day. And within 9 or 10am, they start collecting rubber. As the day grows old, rubber gets thinner and the productions get lesser as well. So, they get busy in collecting rubber every morning. Milk-like raw material of rubber, in liquid form known as 'latex', is collected from tapped trees.