Jute dilemma

Khalid Rab

|

Photo: Hemanta Nath/Driknews |

IT has been recognized that Jute and Allied fibers occupy a unique position as eco-friendly, bio degradable, renewable natural fiber. We should also understand that Jute sector of Bangladesh has made and continues to make significant contribution to the national economy. Apart from its versatile use from domestic area to industry, it protects environment from different ways. All the export earnings from the Jute Industry vis-à-vis Jute sector are net foreign currency earnings. Domestic value additions is exceptionally high. So, a viable Jute Industry would be an ideal type of activity for the economic development of the country. We should always consider that Jute Industry is indigenous one. Jute, of the best quality in the world, is available in Bangladesh. It is one of the few natural resources that the country has and it has provided Bangladesh with a comparative edge in the world trade in jute goods.

Over the past decade, the jute industry has suffered more downs than ups for no fault of its own. It has been allowed to suffer gradual decline mainly due to lack of appropriate policy actions.

Jute ndustry in Bangladesh (erstwhile East Pakistan) was established as export oriented industry with the aim of rapid industrialization. It became the major source of foreign currency earnings. The industry was made viable and kept expanding with the Govt. financial assistance on export of jute goods through bonus voucher.

After liberation of the country in 1971 and nationalization of the Industry in 1972, such financial assistance to Jute Industry was withdrawn and the Industry started incurring losses. On the other hand, the newly established BJMC had to concentrate mainly on rehabilitation of the war torn Jute Industry and expand the world export market share which was taken by the competitors during war of liberation. At the initial stage Bangladesh Jute Industry i.e. BJMC had to face serious problems to recover the lost market.

By the untiring efforts to improve the management, production and export, the Industry i.e. BJMC started achieving positive results from 1973-74 with the production of 500 thousand tons and export of 445 thousand tons from 320 thousand tons and 225 thousand tons respectively of 1971-72.

In 1977-78 BJMC could achieve an export of 531 thousand tons, mainly traditional products (hession, sacking & CBC) against the previous highest export of 506 thousand tons in 1969-70. In 1980-81 Jute Industry could achieve highest production of 590 thousand tons exceeding the production of 1969-70. In 1981-82, the Jute Industry again could break the export record of 1969-70, exporting around 537 thousand tons against production of 586 thousand tons.f

Large scale denationalization started in 1982-83. But, private sector jute mills could not perform the way it was expected for many reasons. As a result, performance of the overall Jute industry started deteriorating gradually from 570 thousands tons (production) and 514 thousand tons (export) in 1982-83 to 286 thousand tons (production) and 192 thousand tons (export) in 2003-04.

During Eighties the new jute yarn/twine mills came into the picture and expanded gradually. It could increase export of yarn/twine from 28 thousand tons in 1983-84 to around 380 thousand tons in 2009-10. The gradual increase in the production and export of yarn/twine could help increase of overall export of Jute products to nearly 600 thousand tons with the share of only around 200 thousand tons of traditional products i.e. Hessian, sacking & CBC.

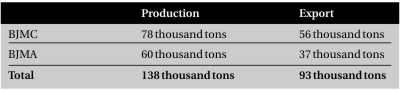

It may be seen from the figures given below that production and export of BJMC and BJMA mills (mainly traditional products) recorded gradual decline over the years:

Position in current financial year is also not encouraging in BJMC & BJMA mills as may be seen from the figures (6months/ July-Dec'10) below:

However, the production and export of yarn/twine mills mainly under BJSA (Bangladesh Jute Spinners Association) recorded increase gradually from 50 thousand tons and 28 thousand tons in 1983-84 to 399 thousands tons and 380 thousand tons in 2009-10 respectively. It may be maintained during this financial year also on the basis of its production and export of 227 thousand tons and 193 thousand tons of July-Dec'10.

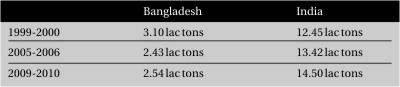

Figures given below on the comparative position in production of traditional products reveals that while Bangladesh jute industry is sinking, Indian jute industry is booming:

The present govt. has taken some positive steps to revitalize the Jute Industry, particularly BJMC mills. But, piece meal action will not serve the purpose.

Because, production and export of traditional products, both in BJMC and BJMA (private) mills recorded gradual decline to a frustrating level over the years.

Total figures are not available readily, it reveals from some of the available figures that export of BJMC in the major importing regions e.g. Australia, America, Middle East, Europe, Africa recorded sharp decline in recent years mainly because of decline in production and absence of effective marketing efforts.

Present situation of the industry calls for immediate measures/actions in the following areas:

* The new challenges and opportunities presented by the changing global environment of integration in the development of natural fibers;

* Modernize the jute industry to improve efficiency in production and processing to reduce cost and enhance product quality. With the rise of inescapable competition facing our jute sector, in the international field it should be our endeavour to facilitate upgrading the skills of the Workers, Supervisors and Managerial staff who are employed in the Jute Industry.

* Involve and ensure the active co-operation and partnership of Corporation, Financial Institutions, Energy supplying Agencies and Entrepreneurs in the fulfillment of these objectives.

* Power shortage should be reduced either by power supplying agencies or by setting up generators (gas or diesel) in such mills where it is required.

* The efforts need to be put with all earnestness to bring the efficiency level to at least 80%.

* So far management at the mill level is concerned, it should be linked to productivity and efficiency.

* Enable the jute industry to build world class state-of-the-art manufacturing capabilities in conformity with environmental standards, and for this purpose, to encourage Foreign Direct Investment as well as research and development in the sector.

* Aggressive marketing measures need to be undertaken internationally.

* Markets like Africa and Middle East should be given top priority to recover the lost market.

The author is a jute expert and the views expressed by him are his own and not of the jute commission of which he is a member.