Inside

|

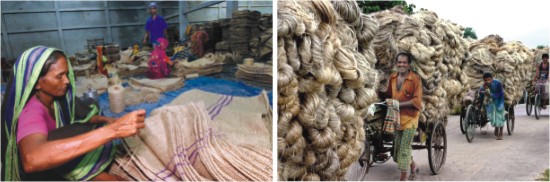

Golden Opportunity Is privatisation the answer to revive the fortunes of the jute industries, asks Zahin Hasan The long decline of the jute industry is a chapter of our history which we are already forgetting. It has become popular to blame the World Bank and IMF for forcing the government to close BJMC jute mills. But the fact is that competition from cheaper synthetic substitutes (such as woven polypropylene sacks, which have replaced jute sacks for most applications) is what killed the jute industry.

If the jute mills had not been nationalised in the 1970s, competition from synthetics would have forced the jute industry to become more competitive by increasing both productivity per worker and productivity per machine. This is not rocket science. It requires investing money in machine maintenance and improvement, and in giving workers incentives to be more productive. After the jute mills were nationalised, BJMC never took any steps to become competitive. We never had a government which viewed BJMC jute mills as businesses which must be run profitably and expanded. Governments were solely interested in rewarding their supporters with jute mill jobs; BJMC mills were packed with high numbers of unnecessary workers. Businessmen view excess workers as an excess cost. Politicians view excess workers as happy voters. Productivity of BJMC jute mills declined continuously for years and years because money which should have been spent on machine maintenance (to say nothing of machine improvement) was paid out as wages to excess workers. As the loss-making mills could not afford to buy spare parts, they cannibalised parts from some machines to keep others running. Gradually more and more cannibalised machines were reduced to useless piles of scrap metal; productivity plummeted. Low productivity is not the only reason why BJMC jute mills run at a loss. It is well known that corruption is endemic in BJMC mills, particularly in jute purchasing. Many BJMC mill managers receive kickbacks from jute suppliers in exchange for accepting low-grade jute at a high price. However, low productivity probably costs BJMC more money than corruption. Peoples Jute Mill is a case in point. With the equipment it had, Peoples Jute Mill should have been able to produce over 70 tons of jute goods per day. To do so it should have required no more than 3,500 workers (50 workers per ton of output per day). Under BJMC management, output fell every year until it reached the abysmal level of only 13 tons per day (just before it was finally closed). During its long period of declining production, excess workers were not shed.

If Peoples Jute Mill had been run by an entrepreneur, machine maintenance would have been prioritised; output per machine would not have been allowed to fall. Excess workers would have been shed to make cash available for machine maintenance (and improvement). State owned companies like BJMC will probably never become profitable, because politicians will not allow them to shed excess workers. With the rising price of petroleum, the government's budget is under increasing strain. Diesel is widely used to fuel irrigation pumps; the government continues to sell diesel at a heavily subsidised price rather than incur the wrath of millions of farmers. Governments of rich countries can afford to buy popularity by paying subsidies. Bangladesh and other poor countries face tough choices. Continuing fuel subsidies means that other subsidies -- like subsidies to loss-making BJMC jute mills -- must stop. Increasing petroleum prices have had another effect. All petrochemicals -- including synthetic substitutes for jute -- have become more expensive. Demand for jute products is increasing. This is why entrepreneurs are once again becoming interested in jute. Kazi Farms Limited, a company primarily involved in breeding chickens and manufacturing poultry feed, has recently leased Peoples Jute Mill from BJMC. Another jute mill, Daulatpur Jute Mill, was recently offered for sale to the private sector, but the Privatisation Commission stopped the process as (in their opinion) the bids submitted were too low.

The Privatisation Commission's decision to stop the privatisation of Daulatpur Jute Mill reflects its failure to understand private-sector decision making. When an entrepreneur considers purchasing an existing business, he starts by calculating how much profit it is likely to make. Normally, a "fair" purchase price is held to be the amount of profit which the business is likely to make in the next four or five years. In other words, if I invest money to buy a business, I would like to make that money back in four or five years. The low bids submitted for the purchase of Daulatpur Jute Mill were justified, given the fact that jute is a low-margin business. If the Privatisation Commission's objective is to sell a jute mill to an entrepreneur who will actually operate the mill, they will have to agree to a modest selling price which reflects the modest profitability of the jute industry. On the other hand, if the Privatisation Commission's objective is to sell a jute mill's assets at the highest possible price, then they should first auction all the jute processing machines, then auction each building separately (with its own plot of land) to the highest bidder. This is what a corporate raider would do if he were to buy a jute mill with the objective of liquidating it at a profit. Each jute mill has huge assets in terms of land and buildings. Many smaller factories could be set up if these assets were broken up and sold separately. That would not necessarily be a bad thing. It is quite likely that the total employment and profits created by many smaller factories would be higher than the employment and profit created by one large jute mill. I think it would be hasty to break up BJMC jute mills into pieces and sell the pieces. Across the border in West Bengal, many private sector jute mills make a profit even though Indian workers are paid higher wages. These mills have invested a lot of money in improving their machines (which are in many cases almost a century old) and have made workers accept that higher wages must be justified by higher productivity. In stark contrast, the state-owned mills in India are just as badly run as BJMC mills. The Bangladeshi jute industry has a lot to learn from the India. Our goal must be to eventually match the productivity of the private sector jute mills in India. This can be accomplished in just a few years if every Bangladeshi jute mill employs Indian technicians to improve their machines and train their workers.

Most large industrial companies in Bangladesh employ foreign technicians and consultants in order to achieve international standards of productivity and quality. This is true of the garments industry, the textile industry and even the poultry industry. Why should the jute industry be any different? The answer, of course, is that it should not be any different. In a global marketplace, the companies to survive will be the ones which achieve international standards of productivity and quality. Zahin Hasan is a director of Kazi Farms Limited. His views do not necessarily reflect those of his company. |