| Behind the Scene

From Bogra

The Village of the Carpenters

Selina Sheuly

WHEN the month of Boishakh comes around the village fairs begin. All kinds of festivals start taking place in the villages, like the 'jamai-boron' party. Among the things being sold at the fair are beautiful wooden furniture. Not only are there beds, alnas, chairs and tables, there are show cases, dressing tables and sofas as well. Now the question is, where is this furniture made? Looking for the source, I stumbled upon a village where the entire village was involved in carpentry and woodwork. The name of the village was Uttarpara and it was part of Bogra's Gabtoli upazila, Rameswarpur Union. WHEN the month of Boishakh comes around the village fairs begin. All kinds of festivals start taking place in the villages, like the 'jamai-boron' party. Among the things being sold at the fair are beautiful wooden furniture. Not only are there beds, alnas, chairs and tables, there are show cases, dressing tables and sofas as well. Now the question is, where is this furniture made? Looking for the source, I stumbled upon a village where the entire village was involved in carpentry and woodwork. The name of the village was Uttarpara and it was part of Bogra's Gabtoli upazila, Rameswarpur Union.

Three kilometers from Bogra city, six kilometers east of Matidali bazaar you will find Peergachha bazaar. The village right next to this bazaar is Rameswarpur Uttarpara. The men and women in this village are tirelessly involved in making furniture. This is why this village is known as “Kath Polli” or “Mistri para”.

I wanted to find out when the village started producing wooden furniture so I had to go around the entire village. Finally I met a man who started making wooden shoes. This 65-year-old man told me how this village developed through this trade. He told me that once he and a few others would go around cutting wood with a saw. They were professional woodcutters. This turned into a tree-trunk selling business. They would buy tree-trunks from households and sell at various saw-mills. After that, these guys concentrated on their own carpentry business.

He started out with making wooden shoes. He used to do this himself. Later he made more things to meet demand- like sitting tools, chairs, light stands. After he became pretty accomplished making these, he couldn't go back to being just a woodcutter anymore. Later he took all the stuff he made and tried to sell them at the marketplace. The markets included Naruyamala, Ghoradhap, Mahastan, Shibganj, Sihali and Namuja Haat. His goods would also be sold at fairs.

By interacting with customers, they found out about market demand a lot better. By understanding what the customers really wanted, their carpentry style also changed. After this, they started making tables and chairs. Now this village is making beds, show cases, dressing tables and sofa sets. Most of the families of the village are excited about the beds though. This is because less wood is required and less time is needed to make the beds. This is why beds are cheaper as well.

Pretty much every household in this village is now making wooden furniture. There are now eight big furniture-making factories in the village. There are 10 workers in Shahjahan's factory, 7 workers in Shamsul Haq's factory, 6 workers in Golam Qader's factory, 10 workers in Nannu Sarikader's factory, 7 workers in Badshah Pramanik's factory and 4 workers in Mozaffar Pramanik Babu's factory.

After talking to the owners and workers of this factory, I found out that in order to make inexpensive furniture, they do not have to travel around much. Their village is surrounded by 11 saw-mills. All their raw material comes from these saw-mills. After talking to the owners and workers of this factory, I found out that in order to make inexpensive furniture, they do not have to travel around much. Their village is surrounded by 11 saw-mills. All their raw material comes from these saw-mills.

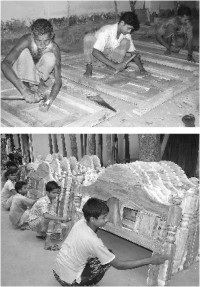

About 200 families from this village rely on this industry to put food on the table. There is probably not a single individual in this village that wouldn't be able to make a wooden stool on their own. Kids get involved in this trade very early. They start with chopping the wood, cleaning it, shearing the wood, and then painting it. The factories are electrically powered. A lot of the work is done with power tools.

Some factory owners informed us that their stuff is sold not only inside their own district, but in other districts as well. Every day, their wares are bought up by the Rangpur bazaar, Joypurhat, Pabna and Gaibandha's Golapbagh. The factory owners told us they mostly get jobs for making beds and doors. On wholesale, they sell each bed for taka 1,500 and each door sells for about taka 700 to taka 800. In the regular market, beds are sold for taka 2000 and doors are sold for somewhere between taka 900 and taka 1000.

A lot of people in this village have turned their fates around working in this trade. Among them are Shahjahan Sakidar and Shamsul Haq. Shahjahan Sakidar admits that his father started out as a woodcutter, so he had been working with wood for as far back as he could remember. When he grew up he started making furniture. Then there was no turning back. “I now have 5 bighas of land. It grows the rice that my family eats. Back in my dad's day, we had a tin house. Now we have a solid brick house. I have nothing left to desire.”

It's not just that the factory owners are becoming better off. The workers are getting better wages. One complaint they do have, however is that they cannot work after dark because the electricity is turned off. This is making them work and earn below their capacity. So far, this industry has risen entirely through the efforts of the villagers. There has been no government assistance. The locals are proud of what they have done. They say that their efforts are enabling the poor people around to sleep on beds.

Copyright

(R) thedailystar.net 2008 |